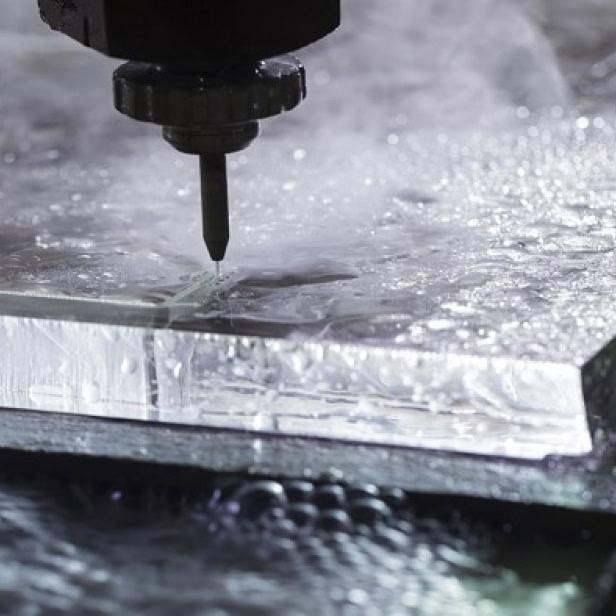

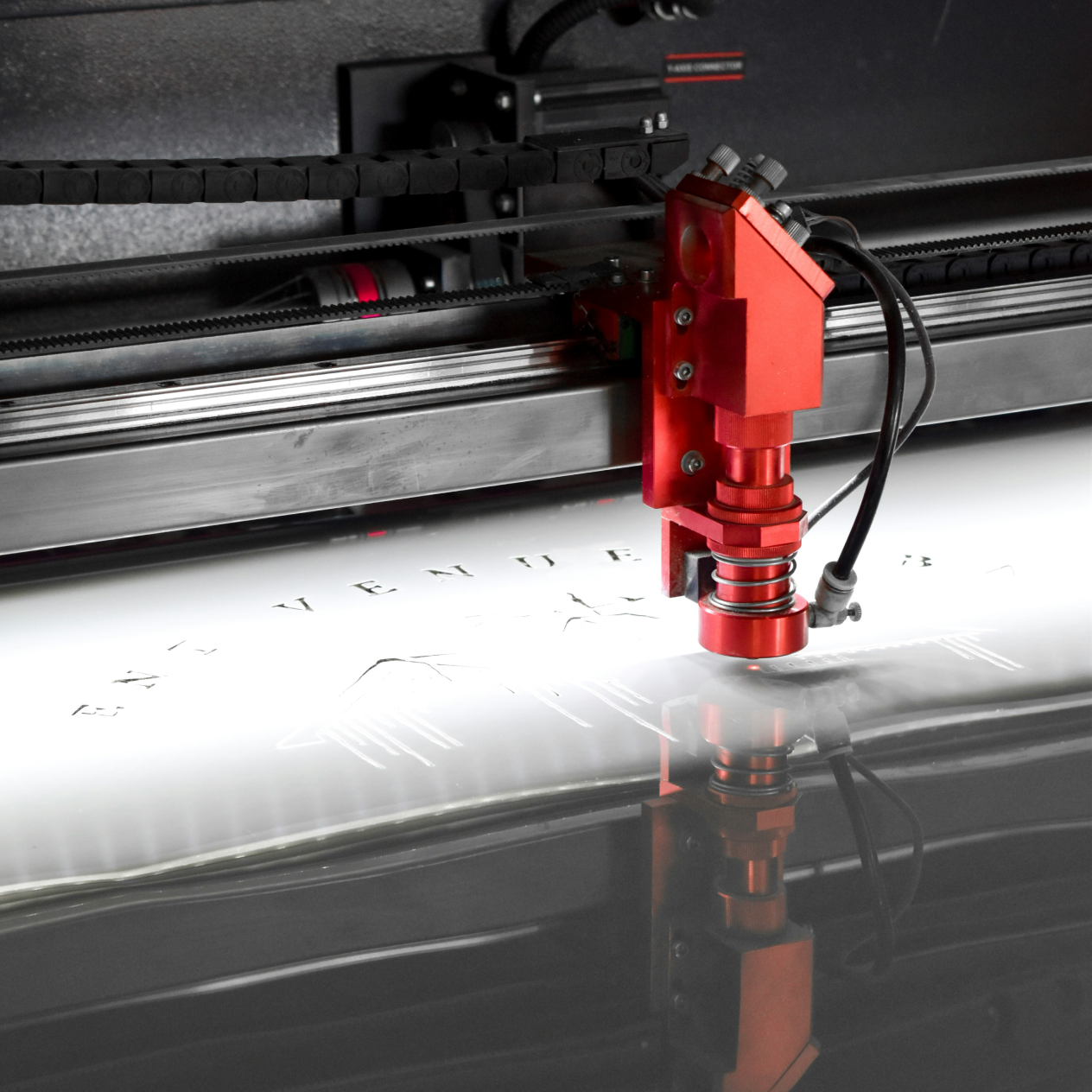

CNC Routing & Finishes

Durability: Powder coating provides a more durable finish than most other painting methods, which is ideal for both outdoor sculptures and metal parts exposed to the elements in restoration projects.

Aesthetic Flexibility: Available in a wide range of colors and finishes, powder coating can be tailored to match the original appearance of historical pieces or to suit the artistic vision of a sculpture.

Environmental Impact: Powder coatings emit zero or near zero volatile organic compounds (VOCs), making them a more environmentally friendly option than liquid paints.

Restoration: Powder coating is used in the restoration process to not only restore but also protect historical and architectural metal works. Its ability to resist environmental damage makes it an excellent choice for preserving the integrity and appearance of metal components.

Sculpture: Artists choose powder coating for its vibrant finishes and robust protection, ensuring that their sculptures withstand the test of time and maintain their color integrity under various environmental conditions.