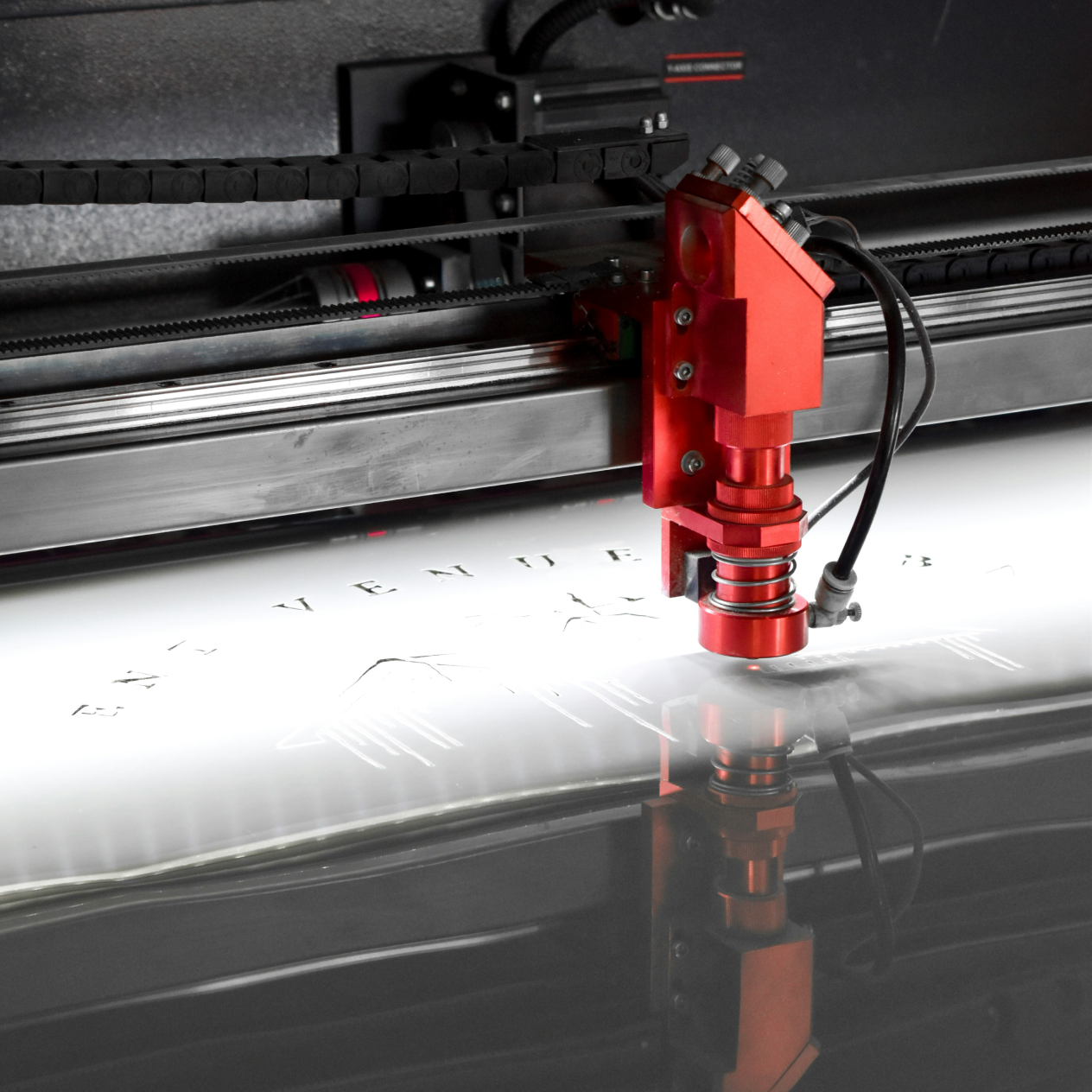

Laser Cutting

Laser cutting is a technology that uses a high-powered laser to cut materials into custom shapes and sizes. From metals and acrylics to fabrics and leathers, laser cutting can handle diverse materials, providing clean cuts and intricate detailing that are difficult to achieve with traditional cutting methods.

Known for its clarity, durability, and flexibility, acrylic is an ideal medium for an array of applications—from intricate artistic designs to robust industrial parts. This guide delves into the process of laser cutting acrylic, highlighting its advantages, common uses, and tips for achieving the best results.

Laser cutting allows for extremely precise cuts, achieving intricate details that are impossible with traditional cutting methods. The laser beam seals the edges as it cuts, resulting in a polished, high-quality finish without additional processing.

Acrylic’s transparency and resistance to the elements make it an excellent choice for both indoor and outdoor signs. Laser-cut acrylic signs are commonly found in retail, corporate, and public settings.

Compared to mechanical cutting methods, laser cutting significantly speeds up the production process. It allows for rapid prototyping and quick turnarounds on projects, which is crucial in fast-paced manufacturing environments.

Laser cutters can easily handle complex patterns and fine details. This flexibility makes it a preferred method for projects requiring high degrees of customization, such as signage, jewelry, and decorative panels.

The precision of laser cutting minimizes material waste, making it a cost-effective and environmentally friendlier option. By optimizing cutting paths, manufacturers can maximize the use of each acrylic sheet.

Materials Suitable for Laser Cutting

Each material brings its own unique properties and challenges to the laser cutting process. From natural materials like wood and leather to synthetic options like acrylic and plastic, understanding how each reacts under the laser helps in maximizing the technique’s potential. Here’s a look at some commonly laser-cut materials, their characteristics, and their applications.

Acrylic is a favored material for laser cutting because it leaves a beautifully polished edge post-cut. It’s available in a variety of colors and thicknesses, which lends flexibility to projects. Acrylic is widely used for signage, retail displays, and intricate decorative items. It’s also popular for prototypes and parts in engineering projects.

Leather can be both laser cut and engraved, which adds functionality and aesthetic detail. The laser process can produce precise cuts and etchings, perfect for detailed patterns. Common uses include fashion accessories like belts and bags, footwear, and custom tags.

Rubber cuts well with a laser, allowing for clean, precise edges. Laser-cut rubber is typically used for industrial purposes due to its ability to create detailed and durable parts. Common uses include rubber gaskets, seals, and custom stamps.

Wood is a popular choice for laser cutting due to its natural beauty and ease of cutting. Different types of wood, including plywood, MDF, and solid hardwoods, can be laser cut. Each type has its own characteristics, such as grain density and resin content, which can affect the cutting process. Wood is used for decorative items, furniture, puzzles, and artistic sculptures. It’s also favored for architectural models and signage.

Paper is perhaps the easiest and fastest material to cut with a laser. It allows for extremely intricate cuts without physical contact, which means no part of the paper warps or tears during processing. Laser-cut paper is used for invitations, business cards, artwork, and intricate decorative pieces.

Fabric laser cutting is efficient and precise, allowing for detailed cuts without fraying the edges. It works with a wide range of textiles, including cotton, felt, silk, and polyester. Used extensively in the fashion industry, laser-cut fabrics are ideal for intricate designs on apparel and decorative textiles. It’s also used for creating unique patterns in home décor.

Industrial and Commercial Use: Businesses in Manhattan often require precise components like custom gears, machine parts, or signage. Metal laser cutting services cater to these needs with exactitude, ensuring that even the most complex parts meet rigorous industry standards.

Creative and Decorative Projects: Artists and designers frequently leverage laser cutting for its ability to produce intricate patterns and delicate cuts. Wood laser cutting and fabric laser cutting services are popular for creating decorative items, fashion pieces, or detailed art installations.

Prototyping and Development: For startups and developers, rapid prototyping is essential. Laser cutting services in Manhattan accelerate the development process by enabling fast and affordable production of high-quality prototypes.

Accessibility and Quick Turnaround: Choosing a laser cutting shop near you in Manhattan means faster turnaround for projects and easy access to in-person consultations.

High Precision and Quality: With advanced CNC laser cutting technology, services in NYC ensure high precision in every project, which is critical for both aesthetic and functional quality.

Customization and Flexibility: Custom laser cutting services offer extensive flexibility, allowing clients to bring almost any vision to life. Tailored projects can range from small custom pieces to large-scale productions.