Sandblasted Signs

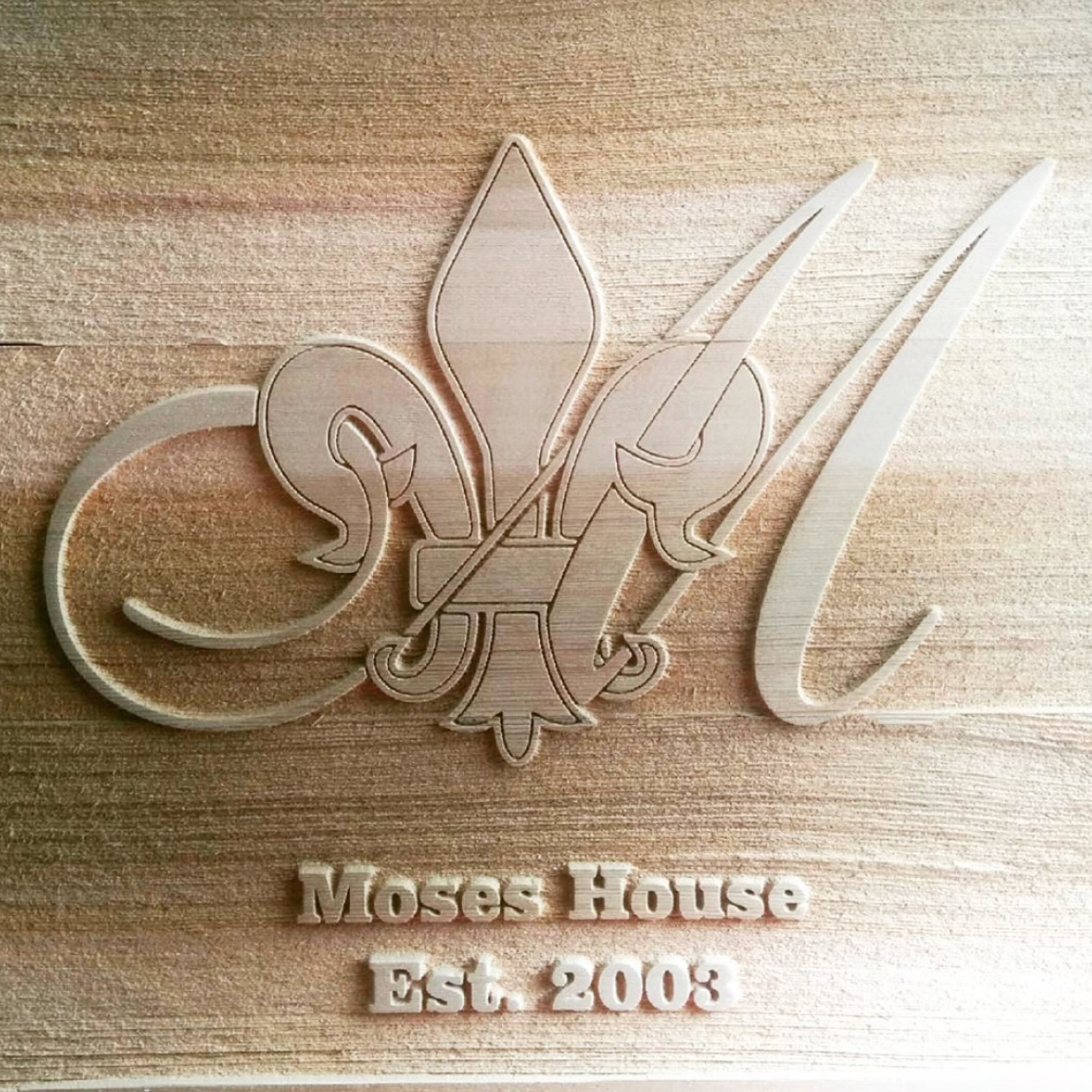

Sandblasted signs involve a process where a portion of the sign material’s surface is eroded away by sand particles blasted against it under high pressure. This method creates a textured effect where the design elements are either raised or recessed, depending on how the mask is applied. The result is a sign that has depth and a notable artistic quality.

Sandblasted signs

Wood: Cedar and redwood are the most common types of wood used for sandblasted signs due to their natural resistance to decay and insects. Wood provides a traditional, warm look that is highly sought after for certain types of businesses.

High-Density Urethane (HDU): HDU is increasingly popular for sandblasted signs because it is easier to control during the sandblasting process and does not have the natural imperfections that wood can have. HDU signs are lighter, easier to transport, and can withstand severe weather conditions without warping, cracking, or rotting.

Texture and Depth

The textured surface and three-dimensional appearance of sandblasted signs offer a level of sophistication and elegance that printed or vinyl signs typically cannot achieve.

Durability: Both wood and HDU are durable materials suitable for outdoor use, and with the right finish, a sandblasted sign can last for decades even under harsh environmental conditions.

Customization: Sandblasted signs can be customized in a variety of ways, including shape, size, color, and design, allowing them to perfectly match the architectural style and branding of any business or locale.