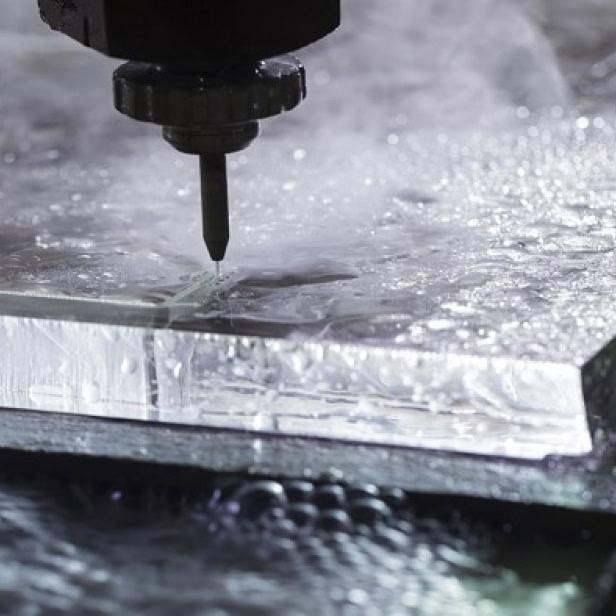

Waterjet Cutting

This technology uses a high-pressure stream of water, often mixed with an abrasive substance, to cut through materials without the heat damage associated with methods like laser or plasma cutting. Here are some of the common materials that can be effectively cut using waterjet technology:

- Metals: Waterjet cutting is highly effective for cutting all types of metals, including steel, stainless steel, aluminum, copper, brass, and titanium. It’s especially beneficial for metals as it doesn’t introduce heat-affected zones (HAZ), preserving the metal’s structural integrity.

- Stone and Tile: Waterjet is extensively used in the tile and stone industries for cutting intricate designs in marble, granite, quartz, and ceramics. It’s perfect for creating detailed inlays and complex edges.

- Glass: Waterjet cutting can precisely cut glass without risking cracks or breaks, making it suitable for cutting bullet-proof glass, stained glass, mirrors, and more. It allows for intricate cuts and shapes that are difficult with conventional glass cutting tools.

- Foam and Insulation: Waterjets can slice through foam and insulation materials cleanly and with great accuracy, ideal for packaging solutions and industrial applications.

- Textiles and Fibers: Waterjet technology is used in the textile industry to cut synthetic fabrics, fibers, and even leather. It ensures clean cuts without fraying the edges, which is often a challenge with traditional cutters.

- Wood and Laminates: Waterjets can cut wood and laminated materials without the risk of burning or chipping the material, suitable for custom furniture, cabinetry, or intricate wooden inlays.

Industrial Fabrication: In Manhattan’s diverse manufacturing landscape, waterjet cutting is essential for creating complex parts with high precision. It is widely used in fabricating machine components, automotive parts, and aerospace elements due to its ability to cut through hard materials like metals and ceramics without altering their intrinsic properties.

Architectural and Decorative Projects: Architects and designers in NYC leverage waterjet cutting for its excellent accuracy and versatility. It is used to create decorative elements, custom fittings, and intricate installations that require meticulous detail and fine craftsmanship.

Artistic Creations: Many artists prefer waterjet cutting to bring their intricate designs to life, especially when working with challenging materials like glass or stone. The technology supports their creative vision by enabling detailed cuts that maintain the integrity of the materials.

No Heat-Affected Zones: Waterjet cutting does not generate heat, preventing the alteration or warping of materials. This is crucial when working with complex materials that are sensitive to high temperatures.

Environmentally Friendly: This method is one of the more environmentally friendly cutting processes available. It produces no hazardous waste and minimizes leftover scrap material, aligning with Manhattan’s increasing focus on sustainable practices.

Material Versatility: Waterjet cutting can handle almost any material, from metals and glass to composites and plastics, without the need for multiple cutting systems.

Precision and Efficiency: With advancements in CNC (Computer Numerical Control) technology, waterjet machines can produce highly accurate cuts quickly, significantly reducing turnaround times for projects in fast-paced environments like Manhattan.